Personal Account

Personal Account

Electron beam welding plant "ELU-27"

Electron beam welding plant "ELU-27"

Description

The plant "ELU-27" for electron beam welding of circumferential and longitudinal seams on cylindrical products

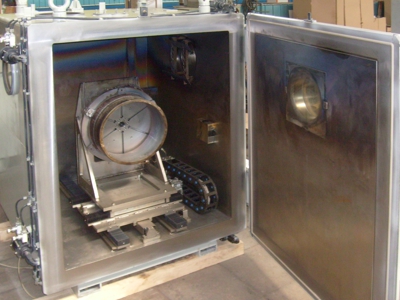

The plant "ELU-27" is intended for electron beam welding of circumferential and longitudinal seams on cylindrical products made of stainless steel, heat-resistant and titanium alloys, as well as brush seals.

The plant consists of the blocks:

- working chamber;

- electron beam gun;

- rotator;

- longitudinal movement mechanism;

- transverse movement mechanism;

- vacuum station;

- high-voltage stabilized power unit BEVS-60/15;

- pneumatic system;

- water cooling unit;

- control system.

The working chamber is designed to create a vacuum environment in the area of welding products with an electron beam.

The camera has three viewing windows: one each on the camera and door - for visual observation; one - on the upper wall of the chamber - for installing control and measuring instruments. The viewing windows from inside the chamber are protected from spraying and are also equipped with double high-strength glass for protection against X-ray radiation.

A distinctive feature of the welded structure of the chamber of the "ELU-27" plant from conventional welded structures is the presence of two vacuum-tight and durable shells, the outer one - welded from simple sheet steel and the inner working one - welded from stainless steel 12Х18Н10Т.

The working chamber contains:

- product manipulator, consisting of a rotator, mechanisms of longitudinal and transverse movements;

- camera lighting system;

- glass protection system from spraying.

The vacuum station of the installation ensures that a vacuum is obtained in the working chamber. Air is admitted into the working chamber through a dust and moisture filter located on the connecting flange of the vacuum system to the chamber.

The water cooling system is designed to cool the pumps of the vacuum station. The presence of water in the cooling channels is monitored at the outlet using non-contact induction sensors. If there is no water at the drain, an alarm signal is issued.

The chamber lighting system provides illumination of the welding area, necessary for the normal functioning of the surveillance system and visual control by the operator, has two types of lighting: using lamps mounted on the ceiling of the chamber, at atmospheric pressure in the chamber, and two tungsten open spirals at operating pressure.

The energy complex of the "ELU-27" plant includes: an electron-optical system - an electron gun (EPN-60/15), a high-voltage power supply (BEVS-60/15), power supplies for magnetic lenses and cathode filament, management and control systems.

The plant consists of the blocks:

- working chamber;

- electron beam gun;

- rotator;

- longitudinal movement mechanism;

- transverse movement mechanism;

- vacuum station;

- high-voltage stabilized power unit BEVS-60/15;

- pneumatic system;

- water cooling unit;

- control system.

The working chamber is designed to create a vacuum environment in the area of welding products with an electron beam.

The camera has three viewing windows: one each on the camera and door - for visual observation; one - on the upper wall of the chamber - for installing control and measuring instruments. The viewing windows from inside the chamber are protected from spraying and are also equipped with double high-strength glass for protection against X-ray radiation.

A distinctive feature of the welded structure of the chamber of the "ELU-27" plant from conventional welded structures is the presence of two vacuum-tight and durable shells, the outer one - welded from simple sheet steel and the inner working one - welded from stainless steel 12Х18Н10Т.

The working chamber contains:

- product manipulator, consisting of a rotator, mechanisms of longitudinal and transverse movements;

- camera lighting system;

- glass protection system from spraying.

The vacuum station of the installation ensures that a vacuum is obtained in the working chamber. Air is admitted into the working chamber through a dust and moisture filter located on the connecting flange of the vacuum system to the chamber.

The water cooling system is designed to cool the pumps of the vacuum station. The presence of water in the cooling channels is monitored at the outlet using non-contact induction sensors. If there is no water at the drain, an alarm signal is issued.

The chamber lighting system provides illumination of the welding area, necessary for the normal functioning of the surveillance system and visual control by the operator, has two types of lighting: using lamps mounted on the ceiling of the chamber, at atmospheric pressure in the chamber, and two tungsten open spirals at operating pressure.

The energy complex of the "ELU-27" plant includes: an electron-optical system - an electron gun (EPN-60/15), a high-voltage power supply (BEVS-60/15), power supplies for magnetic lenses and cathode filament, management and control systems.

Technical data

Diameter of welded products, mm

600 - 800

Height of welded products, mm

400

Inner dimensions of the chamber (L*W*H), mm

1300*1200*1500

Ultimate vacuum in the chamber, Pa (mm Hg)

0,007 (5×10-5)

Time to pump out the vacuum chamber to 0.0133 Pa, minutes

15

Maximal air leakage into the working chamber, l Pa/s (l µm Hg/s)

2,6 (20)

Controlled coordinates of product movement

3 (longitudinal, transverse, rotation)

Setting value of longitudinal movement of the mechanism (X coordinate), mm

±350

Setting value of the transverse movement of the mechanism (Y coordinate), mm

±100

Setting value of rotation of the mechanism (coordinate A), °

360

Faceplate diameter, mm

600

Angular speed of rotation, r/sec

0,01 - 0,001

Positioning accuracy, mm

0,1

Overall dimensions (L*W*H), mm

4170*2660*2550

Масса, кг

9000

Submit an inquiry

Прошлое

Настоящее

Будущее

Личный Кабинет

Личный Кабинет