Personal Account

Personal Account

Plant "UMP-500" for deposition of coating

Plant "UMP-500" for deposition of coating

Description

Plant "UMP-500" for deposition of multi-component coatings via gas circulation method

Detailed information PDF

Detailed information PDF

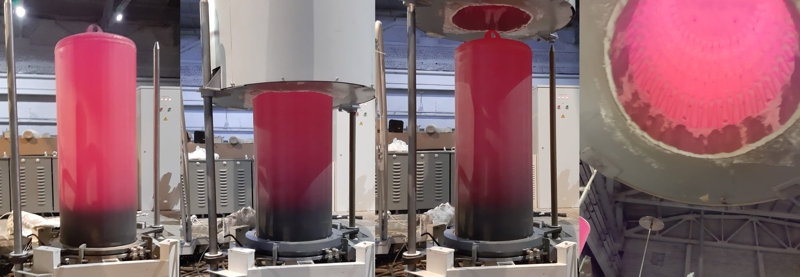

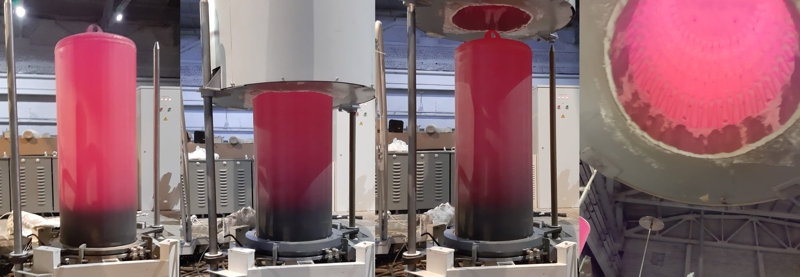

"UMP-500" plant is designed for deposition of protective coatings via gas circulation method.

This method of deposition is used to protect the surface of steel with chromium. Passing vaporous chromium chloride over the surface of steel heated to 1000°C ensures the formation of a chromium coating firmly adhered to the base through an intermediate layer of Fe-Cr alloy with a chromium content of up to 30%. The advantages of the method are the low porosity of the coatings and the possibility of metallization of internal surfaces and parts of complex configurations; the disadvantage is low productivity due to diffusion processes or chemical reactions at the interface.

With the vacuum method, chromed products are either in contact with chromium powder or at some distance from it. The vacuum facilitates the evaporation of chromium and its transfer to the surface being treated. The saturation of the surface with chromium occurs due to the formation of a vapor phase containing chromium at high temperature.

"UMP-500" is a modern equipment and is characterized by a compact design, equipped with a coating reactor.

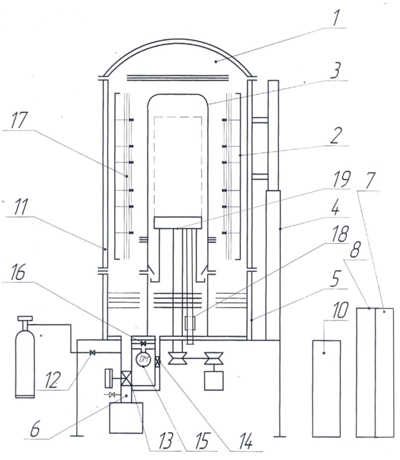

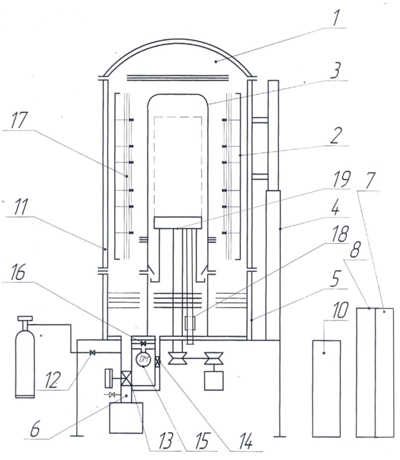

Design of "UMP-500".

The plant consists of main parts:

1. Vacuum chamber;

2. Intra-chamber section of the electric furnace;

3. Screen-heater (muffle);

4. Lifting mechanism;

5. Base;

6. Vacuum system;

7. Control cabinet;

8. Power cabinet;

9. Transformer cabinet;

10. Water cooling system.

This method of deposition is used to protect the surface of steel with chromium. Passing vaporous chromium chloride over the surface of steel heated to 1000°C ensures the formation of a chromium coating firmly adhered to the base through an intermediate layer of Fe-Cr alloy with a chromium content of up to 30%. The advantages of the method are the low porosity of the coatings and the possibility of metallization of internal surfaces and parts of complex configurations; the disadvantage is low productivity due to diffusion processes or chemical reactions at the interface.

With the vacuum method, chromed products are either in contact with chromium powder or at some distance from it. The vacuum facilitates the evaporation of chromium and its transfer to the surface being treated. The saturation of the surface with chromium occurs due to the formation of a vapor phase containing chromium at high temperature.

"UMP-500" is a modern equipment and is characterized by a compact design, equipped with a coating reactor.

Design of "UMP-500".

The plant consists of main parts:

1. Vacuum chamber;

2. Intra-chamber section of the electric furnace;

3. Screen-heater (muffle);

4. Lifting mechanism;

5. Base;

6. Vacuum system;

7. Control cabinet;

8. Power cabinet;

9. Transformer cabinet;

10. Water cooling system.

Technical data

Maximal operating temperature, °C

1000

Uniformity of temperature distribution in the working space, °C

±10

Evaporator temperature, °C

190-220

Carrier gas pressure (argon + chlorides of saturating elements), bar abs.

1.2

Operatinging vacuum up to temperature 600, °C (empty and clean furnace), Pa

6.65

Maximal leakage with an empty, clean muffle, µm Hg × l/s

< 3

Maximal leakage with chloride residues, µm Hg × l/s

< 30

Reactor capacity, l

240

Muffle and cap material alloy

KhN78T (EI 435)

Chamber heating elements alloy

X20N80-N

Heating power, kW

40

Heating zones

3

Weight of cage with equipment, kg

200

Working space dimensions (Ø*H), mm

400*700

Detailed information PDF

Submit an inquiry

Прошлое

Настоящее

Будущее

Личный Кабинет

Личный Кабинет